Warwick House, Unit 7, Long Bennington Business Park, Main Road, Long Bennington, Newark, Notts, NG23 5JR

+ 44 (0) 1400 283090 generaladmin@bfff.co.uk

SHARE THIS POST

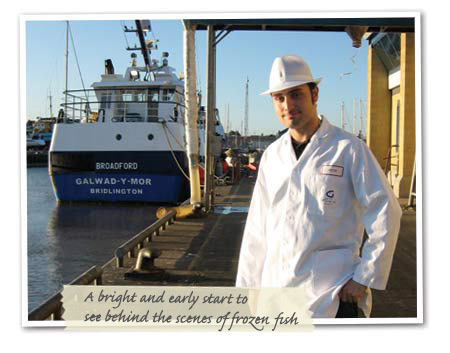

Our ‘Field Operative’ Nick Adams travelled to Grimsby to discover how frozen fish products are produced.

At the break of dawn, Nick paid a visit to Grimsby Fish Market before venturing to Five Star Fish to witness the processes taking place at the factory.

Up before the sun to meet Martin Boyers

Well before the sun had finished rising, I was given a grand tour of Grimsby Fish Market by its chief executive, Martin Boyers. Although I’m not used to waking up anywhere near approaching 5am, Boyers’ enthusiasm for his work was genuinely infectious. He managed to perk me up as he tells me about the morning’s catch. “You can tell these are good quality fish because they’re bright, they’re clean and they show no signs of drying out yet” he excitedly explains as he holds up two typical samples of the fish traded daily on his market.

Once the auctions have ended, a small fleet of forklift drivers begin loading the crates of fish onto their clients’ vehicles. The fresh fish will soon be on its way to a variety of places such as fishmongers, supermarkets, and even factories where it will be manufactured into frozen products. See our Report Videos of Grimsby Fish Market at the bottom of the page.

The buying and selling begins!

A loud chime echoes around the entire building, signalling that it is 7am and time for the frantic fish auctioning to begin at last – exactly what I had come to see! In Grimsby Fish Market, the catches are divided up into three different types: ‘flat fish’ like plaice, ’round fish’ like haddock, and ‘other’ which could mean anything from squid to monkfish. For each of these sub-markets, men with clipboards are surrounded by prospective buyers as they go about trading. Each week sees over one million pounds of sales here and the transactions are finalised very swiftly.

One of the companies who will be creating these said frozen products, Five Star Fish, have agreed to let me see their manufacturing process. After donning a mandatory hair net, plastic jacket and shoe protectors I’m allowed inside.

Watching the skilled technique

The first thing that immediately strikes me about the manufacturing process is the interesting mixture of machinery and human skills involved. Some processes such as filleting the fish are completely devoid of any automated machinery, save for the conveyor belt to move stock around (see my videos at the bottom of this page). It’s hard to imagine a task such as this being done by machines, as the workers effortlessly fillet fish of all shapes and sizes with nothing short of grace, speed and efficiency.

Flash freezing keeps the nutrients locked in

After this comes the integral part of freezing the fish. “We use liquid nitrogen as it creates much smaller ice crystals to preserve the freshness” I’m informed by Danny Burton, managing director of Five Star Fish. Now that the fish have been filleted and frozen, a long production line can now begin. The now frozen fish are placed on a huge series of conveyor belts as they are processed. The conveyor belt leads them to be coated by a waterfall of batter, shortly followed by going through the “Crumbmaster” where the fish become breaded.

A variety of machines of varying designs handle the tasks of packaging their products. One of these machines has a very complex system of weighing fish and grouping them together in order of weight by using several containers. Although it seems to be as if the entire factory’s manufacturing process could quite easily be fully automated, almost every machine is individually maintained by a factory worker. To see the machines in action see our report videos at the bottom of this page.

Although the fish are no longer touched by human hands at this point, there is definitely a high level of care and attention. Factory workers constantly audit their stock using portable computers and overall the efforts are very diligent from the 294 workers at this factory.

What I discovered about frozen fish

From a health perspective, frozen fish products are actually far fresher than any of the other food alternatives on the market. This is because when the fish are caught, they are actually frozen on the ship itself within 4 hours of catch using frozen plate freezers. Freezing is a natural process that doesn’t require any preservatives, so by the time the products reach the consumers they will be clean, fresh, healthy and – importantly – delicious!

SHARE THIS POST

Warwick House, Unit 7, Long Bennington Business Park, Main Road, Long Bennington, Newark, Notts, NG23 5JR

+ 44 (0) 1400 283090 hello@frozenfoodrevolution.co.uk

T&Cs Privacy Policy @bfff frozen food revolution 2025

Website Designed & Built by we are CODA