Warwick House, Unit 7, Long Bennington Business Park, Main Road, Long Bennington, Newark, Notts, NG23 5JR

+ 44 (0) 1400 283090 generaladmin@bfff.co.uk

SHARE THIS POST

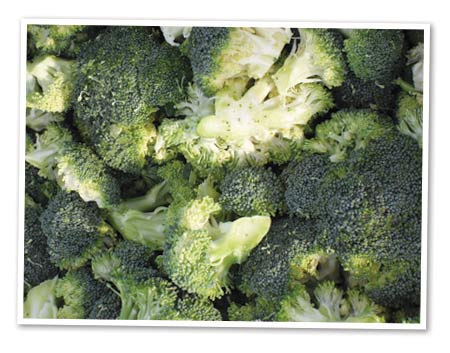

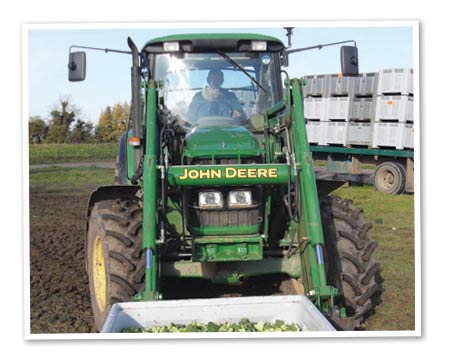

At the Lincolnshire Food Products Cooperative Farming Operations at Holbeach Marsh, near Boston, Lincolnshire I was met by the charming and knowledgeable, Ray Francis, the field manager. He explains to me that the terrain is all ‘reclaimed marsh lands’ – Grade I silt land with good moisture absorption, making it ideal for peas/petits pois, sugar beets, and especially broccoli.

But oh so very, very muddy!

With an under-base of clay, the mud squishes underfoot, leaving this Field Operative wishing she’d given in to the offered wellies! The soil, he continues, is nutrient-rich and allows crops to flourish with abundant periods of sunniness and warmth. There are five rigs in operation at midday. Manual field labourers are strewn across the field, labouriously chopping as well as floretting the fresh broccoli plants for our eventual consumption.

Ray Explains pesticides and sprays

A ground herbicide is used, says Ray, but it has been field-tested and is safe for human consumption. Although this herbicide is added to the same soil before planting, before the crops go in, once the crop is established they smother the weeds, overtaking in their agricultural legacy, as plants are prone to do.

Ray explains fertilizers

“The use of a spray programme starts off with a herbicide for the plant” Ray adds, and if the crop “needs it” an anti-pesticide is added to broccoli plants’ leaves to combat aphids or a herbicide to battle fungal/moisture problems. A fertilizer may also be added if the crop is struggling a bit in the early stages of its growth.

Ray is at pains to make clear that “Each field has a harvest clearance that is performed and cleared prior to harvesting to ensure safety of the crops and that spraying poses no dangers to human consumption.”

Moving to the processing plant at Pinguin Foods UK Ltd nearby, I meet the agricultural produce manager Stuart Ashton who gives me a guided tour of the plant. Stuart tells me that the most important thing to note is that, “Everything is packaged the same day at the processing plant,”

The blanching (preparation) process of frozen vegetables takes no longer than two to three minutes, where the raw vegetables are heated in a blancher, and then chilled immediately in another receptacle.

Stuart says, “Whilst, the lifecycle of a broccoli plant is from field to process and eventually into the supermarket, and while just as labour intensive as fresh, organic vegetable produce, frozen is quite often undersold or beleaguered in the open market”

Dot, one of the Quality Assurance (QA) Processors in the Frozen Foods / Packaging Department said, “It is quite an eye opener, really. The first day I worked here on the line it was with peas. I just couldn’t believe how detailed the process was, from truck to plant and eventually to my table. Amazing!”

Cold storage can house up to 5,000 tons of palleted, stored frozen vegetables which will be shipped out slowly by as late as next June (2009). This, in turn says Ashton, is processed on a per capita, as need by basis, as determined by Pinguin Foods.

Broccoli is a hardy and prolific crop and generally sprouts eight to twelve weeks from being planted. The average time from harvesting of the broccoli to freezing is anywhere from 50 minutes, to several hours.

Ray Francis explains, “Did you know that only about 40 per cent of the broccoli is used for food? The rest of the plant, 60 per cent – the stalk, leaves and roots – are simply chopped up by an agricultural combine and cut down in the field to re-fertilize next year’s offerings. Surprising, isn’t it?” And so this is why frozen foods and frozen ready meals can be sold at such good prices – there is very little wastage.

Stuart Ashton says, “In all, only about six people ever touch the frozen vegetables that come through the processing plant – quite amazing really, when only a few years ago it was twice that number. Machines really are extraordinary, aren’t they?”

There is a positive story to tell about the safety, convenience, quality, taste and nutrition of frozen foods v. fresh foods. It doesn’t sacrifice quality or time in the processing stage, and if anything flash freezing is simply nature’s way of cutting out the needs for artificial preservatives. Freezing produce is the natural way to preserve food!

As I see it, as a consumer, the main differences between organic produce and the frozen foods/vegetables processing station that I’m struck by is mainly this: between products that are for sale at a farmer’s market and those that are brought from the field, fresh and lush to be frozen, it’s really just the intricacy of the operation. The quality remains formidable, the attention to detail is astonishing, and really, the high-quality handling and importance of routine and maintenance, one can’t help being struck by how few steps are added to freeze this produce and get it to our tables.

SHARE THIS POST

Warwick House, Unit 7, Long Bennington Business Park, Main Road, Long Bennington, Newark, Notts, NG23 5JR

+ 44 (0) 1400 283090 hello@frozenfoodrevolution.co.uk

T&Cs Privacy Policy @bfff frozen food revolution 2025

Website Designed & Built by we are CODA